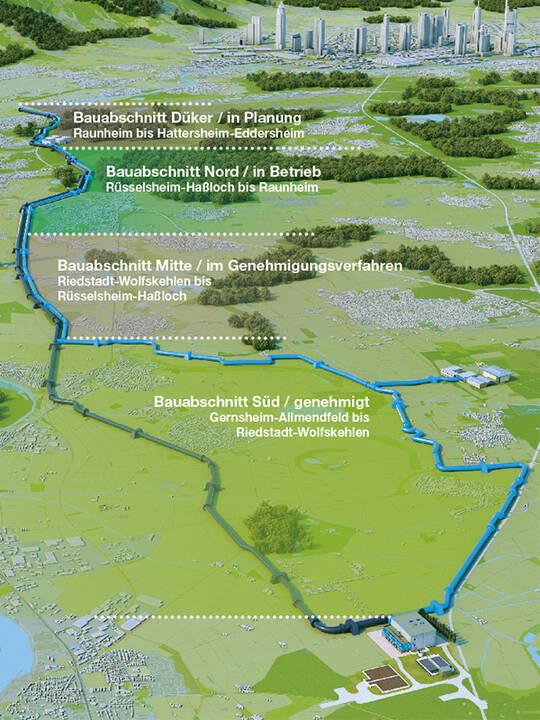

The new Ried pipeline is the largest infrastructure project of Hessenwasser, one of the largest water procurement companies in Germany, for the coming years. The existing pipeline will be joined by a new pipeline in four construction phases along its entire length, which is expected to be completed by the end of 2030. In addition, a redundant potable water transport pipeline will be built west of Darmstadt. The length of the planned steel pipeline with diameters of DN 1000 and DN 1100 will be around 34,8 kilometres in the central and southern sections and will run from the Haßloch pressure boost to the north to the Allmendfeld waterworks to the south. This also includes a connection to the Eschollbrücken waterworks and a new pressure booster system to be built there. The route is partly located in potable water protection areas, crosses various nature and landscape conservation areas and often finds itself in areas with high groundwater levels. DAHLEM provides the technical engineering services for the planning of the construction project, such as the design, approval and implementation planning, as well as preparation and participation in the contract award process. Furthermore, structural design and technical equipment services will also be implemented.

December 2023

KfW is helping Brazil to develop its cities in a sustainable and climate-friendly way. In doing so, the cooperation is helping to reduce climate-damaging emissions and increase the resilience of cities. Special focus is placed, amongst others, on the topic of water. KfW has commissioned DAHLEM with the provision of technical assistance for an urban drainage project in the city of Porto Alegre in Brazil. The aim is to develop a concept with measures for the reorganisation of water bodies and the drainage and management of stormwater. In addition to concept and planning consultation, the project also involves structural and design solutions that take ecological, microclimatic and socio-cultural aspects into account. An initial assessment by DAHLEM experts in an interdisciplinary and international team on site revealed that preventive flood protection in particular is urgently needed. Among other things, extreme weather conditions such as heavy rainfall caused many human casualties and a serious damage to infrastructure due to uncontrolled construction work right up to the water's edge.

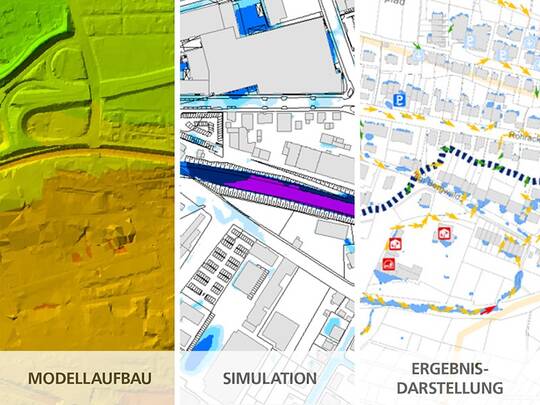

In view of climate change and the related increased potential for heavy rainfall, heavy rainfall prevention is also a key aspect for the City of Darmstadt as a way to address municipal climate protection through climate impact adaptation projects. After being successful in a tender procedure, DAHLEM was awarded by the City of Darmstadt with the preparation of heavy rainfall hazard maps for climate impact adaptation of the city with more than 160.000 inhabitants. Based on the information generated, an action concept with site-specific, centralised and decentralised adaptation and mitigation measures is to be developed, which will be integrated into the climate adaptation concept currently under preparation. The project will be implemented according to the Hessian tendering aid procedure with the following three components: hazard analysis, risk analysis and, based on this, the action concept.

06. - 08. March 2024

The 57th ESSEN CONFERENCE will once again take place at the Congress Center Ost at Messe Essen from 6-8 March 2024 under the motto "Paths to sustainable water management and society". It is the central meeting point for water management experts and will be accompanied by a trade exhibition in addition to the presentations. DAHLEM will be presenting itself here for the first time with an information stand together with three other engineering firms: john becker ingenieure, TUTTAHS & MEYER Ingenieurgesellschaft and IBR Ingenieure. Under the new flag with the logo name aquacor engineering partner, they offer optimal synergy effects in the most diverse specialist disciplines on the basis of many years of trusting cooperation - from the idea to the planning to the implementation of water management projects. Come and visit us at stand no. 1-4 at the Technology Centre to get to know us or, if you already know us, for an exchange of expertise.

INFRASPREE in Berlin is the place to go for two days of knowledge acquisition and networking. InfraSPREE is the industry summit and networking event for all specialists, young professionals, suppliers and consumers from the water industry and technical infrastructure in Berlin and Brandenburg. Here, participants gain theoretical and practical knowledge about state-of-the-art technology. For municipalities, authorities and water boards: Infrastructure renovation and stormwater management with current technologies and future-proof products.

For professionals: information on relevant technologies and live practical application.

For students: Practical experience and contacts with potential employers.

For school pupils: get to know job profiles in water management and infrastructure, talk to experts about development opportunities, look over the shoulders of trainees in the pipeline construction challenge

DAHLEM will also be represented at the congress with an information stand. Let our employees inform you about our range of services.

On April 24th, 2023, as part of the annual series of events of the BIM2Water initiative, a presentation event with an interactive panel discussion will be held on the topic of "BIM in Water Management - Regulations and Practice" at the Hilton Hotel in Düsseldorf, from 11:00 - 17:00h. In addition to numerous practical examples, the participants will gain insights into the current developments of the regulations. Furthermore, the event offers plenty of space for exchanging experience and obstacles in the implementation of BIM in the water industry. DAHLEM is one of the cooperation partners of the BIM2WATER competence initiative, which provides targeted and needs-optimised support to stakeholders in the water industry for digital planning, construction and operation of BIM methodology.

For registration, please check the programme folder available for download

The Darmstadt office can be rightly proud of its expertise in handling risk management projects in municipal flood prevention: For more than 15 years, the area of heavy rainfall and urban flash floods has been built up step by step with considerable know-how. Today, it is one of the branch's most important disciplines. In 2008, the first pilot projects started under the leadership of our employee Dr.-Ing. Marc Illgen, who currently teaches at the University of Kaiserslautern as a professor and continues to accompany us scientifically as a specialist in all aspects of the topic. His activities range, among other things, from memberships in applied research groups worldwide to concepts for climate impact adaptation, guidelines from various federal states and DWA regulations. Since then, in close cooperation with the university, many projects have already been successfully implemented by the staff from Darmstadt using state-of-the-art software, for example for Stuttgart, Frankfurt a. M. or Menden.

Photo left:

Prof. Dr.-Ing. Marc Illgen, Kaiserslautern University of Applied Sciences

Photo right:

Dipl.-Ing. Tim Schneider, Expert for heavy rainfall

Great team spirit and enthusiasm spurred the 20-member DAHLEM team to take part again in this year's Dragon Boat Festival from 11 to 13 August at the Baldeneysee in Essen. As a company active in the water industry, the connection to the water felt extremely harmonious for all team members. In the course of its 90-year history, Baldeneysee has developed from a former industrial river into a body of water that primarily serves as a service and potable water supply and is used as a local recreation area and water sports facility.

The Essen Company Run is known as the sportiest company celebration in the city. At around 30 degrees Celsius, more than 12.000 running enthusiasts gave their best at the 2023 Essen Company Run. The atmosphere was once again outstanding. This is now the 13th Essen Company Run that the DAHLEM running community has been able to record. And once again the motto was: With each other - For each other. A highly motivated Dahlem team went to the start again. "Being there and arriving was the motto". From 7 p.m. onwards, the starting line on Huyssenallee was filled with running enthusiasts. The distance could be covered running or walking. It was not about the competition between the companies, here everyone came together to take account of the sporting event with a lot of fun and at the highest level of commitment.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/1/csm_2020_INFRASPREE_Messestaende_Saal_1_6eb1b263fe.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/2/csm_2023_Folder_BIM2WATER_799faf6466.jpg)