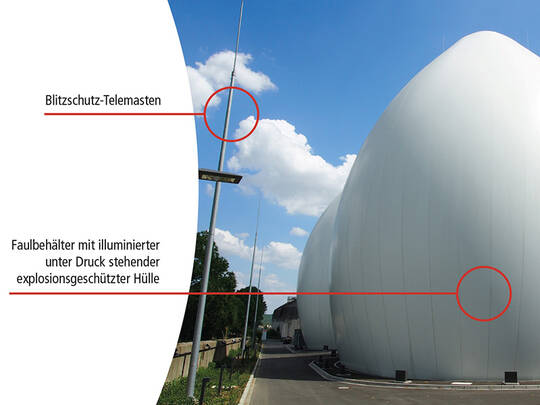

It is a high-tech facility where everything is just about right. With outstanding architecture, a clearly defined purpose and state-of-the-art technology inside, its new digesters are, therefore, characteristic of Würzburg wastewater treatment plant. In the future, 4,500 tonnes of sewage sludge will be produced each year, with an almost tripled annual capacity of 10,000 cubic metres. This means more digester gas and more power generation. 4.2 million kWh of additional electricity can now be produced to be consumed directly on site. As a result of this measure, the CO2 balance improves enormously and the odour nuisance is also reduced. A focal point of the electrical engineering was the integration of the generated energy with the Mainfranken network in line with the Renewable Energy Sources Act. Specifically, the lightning protection system was a considerable planning challenge. Here, it was necessary to, on the one hand, adapt the components of the new digesters and, on the other, to protect their design membrane and the potentially explosive areas against lightning strikes. DAHLEM was responsible for the electrotechnical planning for all service phases.

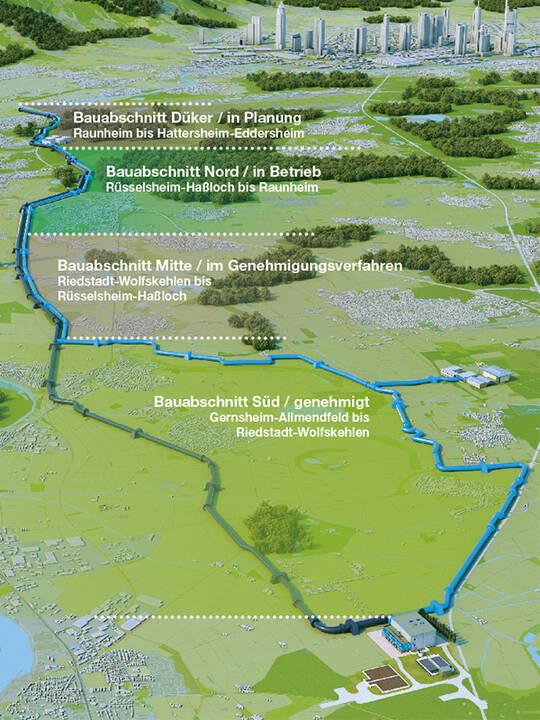

The new Ried pipeline is the largest infrastructure project of Hessenwasser, one of the largest water procurement companies in Germany, for the coming years. The existing pipeline will be joined by a new pipeline in four construction phases along its entire length, which is expected to be completed by the end of 2030. In addition, a redundant potable water transport pipeline will be built west of Darmstadt. The length of the planned steel pipeline with diameters of DN 1000 and DN 1100 will be around 34,8 kilometres in the central and southern sections and will run from the Haßloch pressure boost to the north to the Allmendfeld waterworks to the south. This also includes a connection to the Eschollbrücken waterworks and a new pressure booster system to be built there. The route is partly located in potable water protection areas, crosses various nature and landscape conservation areas and often finds itself in areas with high groundwater levels. DAHLEM provides the technical engineering services for the planning of the construction project, such as the design, approval and implementation planning, as well as preparation and participation in the contract award process. Furthermore, structural design and technical equipment services will also be implemented.

December 2023

KfW is helping Brazil to develop its cities in a sustainable and climate-friendly way. In doing so, the cooperation is helping to reduce climate-damaging emissions and increase the resilience of cities. Special focus is placed, amongst others, on the topic of water. KfW has commissioned DAHLEM with the provision of technical assistance for an urban drainage project in the city of Porto Alegre in Brazil. The aim is to develop a concept with measures for the reorganisation of water bodies and the drainage and management of stormwater. In addition to concept and planning consultation, the project also involves structural and design solutions that take ecological, microclimatic and socio-cultural aspects into account. An initial assessment by DAHLEM experts in an interdisciplinary and international team on site revealed that preventive flood protection in particular is urgently needed. Among other things, extreme weather conditions such as heavy rainfall caused many human casualties and a serious damage to infrastructure due to uncontrolled construction work right up to the water's edge.

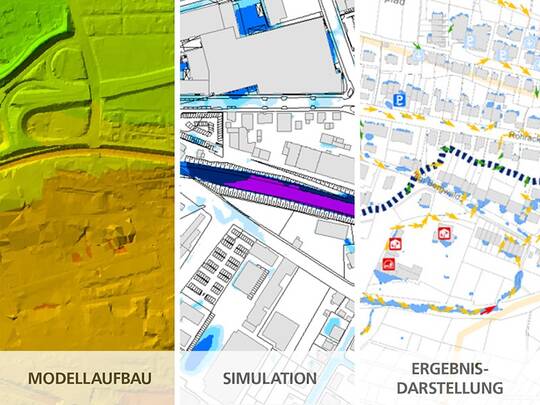

In view of climate change and the related increased potential for heavy rainfall, heavy rainfall prevention is also a key aspect for the City of Darmstadt as a way to address municipal climate protection through climate impact adaptation projects. After being successful in a tender procedure, DAHLEM was awarded by the City of Darmstadt with the preparation of heavy rainfall hazard maps for climate impact adaptation of the city with more than 160.000 inhabitants. Based on the information generated, an action concept with site-specific, centralised and decentralised adaptation and mitigation measures is to be developed, which will be integrated into the climate adaptation concept currently under preparation. The project will be implemented according to the Hessian tendering aid procedure with the following three components: hazard analysis, risk analysis and, based on this, the action concept.

June 2023

After five years of construction, the new Bocksheideweg pumping station in Hamm went into operation. On June 15, 2023, it was officially commissioned by Professor Dr. Ulrich Paetzel, Chairman of the Board of the Emschergenossenschaft and the Lippeverbands, and Dr. Frank Obenaus, Technical Director of the Lippeverbands, and the Lord Mayor of Hamm Martin Herter. The high-performance pumps now transport rainwater and wastewater separately from a depth of eight meters. The plant has a number of special features: it is pedestrian-free and is monitored from outside. With the commissioning of the pumping station, the Heringer Bach and the Hoppeibach have become free of wastewater. The wastewater will be discharged underground in channels and the open wastewater concrete shells will be removed in the future in order to bring about an ecological improvement of the brooks. The pumping station is the final component of a 70 million euro project consisting of new underground sewers, two additional pumping stations and four stormwater treatment plants. The Lippeverband commissioned DAHLEM with the object planning, structural design, technical equipment as well as process engineering in all work phases including construction supervision for the pumping station.

BalWin1 and BalWin2 are the names of the two new offshore connections that feed renewable energy from wind farms in the North Sea to Wehrendorf in Lower Saxony and Westerkappeln in North Rhine-Westphalia into our transmission grid. For both systems, cables will initially be laid on the high seas, in the mudflats near Norderney, and on the mainland between Hilgenriedersiel on the coast and the two grid interconnection points in Lower Saxony and North Rhine-Westphalia. For the most part, they are to be laid in parallel, safely and as environmentally friendly as possible. Both the closed and the "open" construction methods are possible. Amprion commissioned DAHLEM in a joint venture with the planning of an approx. 135 km long underground cable - direct current transmission system (525 kV) from Bösel to Wehrendorf and Ibbenbüren with the rough and fine routing up to and including the submission of the permit application.

On April 24th, 2023, as part of the annual series of events of the BIM2Water initiative, a presentation event with an interactive panel discussion will be held on the topic of "BIM in Water Management - Regulations and Practice" at the Hilton Hotel in Düsseldorf, from 11:00 - 17:00h. In addition to numerous practical examples, the participants will gain insights into the current developments of the regulations. Furthermore, the event offers plenty of space for exchanging experience and obstacles in the implementation of BIM in the water industry. DAHLEM is one of the cooperation partners of the BIM2WATER competence initiative, which provides targeted and needs-optimised support to stakeholders in the water industry for digital planning, construction and operation of BIM methodology.

For registration, please check the programme folder available for download

October 2022

On October 12th, 2022, the Prime Minister of Kosovo, Albin Kurti, officially inaugurated the new fully biological wastewater treatment plant of the municipality of Peja. The wastewater treatment plant was handed over on time and on budget by DAHLEM on a turnkey basis and has already been in operation for one year. The plant is operated by the regional water and wastewater company Hidrodrini. Together with the German and Swiss ambassadors as well as the mayor of Peja and many other guests, the completion of the wastewater treatment plant was celebrated. The entire project was financed mainly by KfW, in cooperation with Kosovo. Likewise, the Swiss State Secretariat SECO and the municipality made substantial contributions to the 23 million euro investment costs, which include not only the treatment plant but also an extension of the sewerage network. WWTP Peja offers a strong contribution to the environmental protection and health care for south-western Kosovo.

You can read more about the Peja sewage treatment plant in the article below.

May 2022

The KEYS research project, which began in 2017 under the leadership of ISAH Hannover, with the participation of DAHLEM and in cooperation with TSINGHUA University Beijing, has now been brought to a conclusion. Various German-Chinese cooperation projects for sustainable water management were developed for the national "Sponge City Concept" in China. In the period 2018-2020, DAHLEM collaborated on two sub-projects in the greater Beijing area, focusing on an implementation-oriented approach of sponge city concepts. Together with the ISAH and the Berlin Water Competence Centre in Germany, project experiences were transposed into an element catalogue showing needs-based solutions of the sponge city concept for the local metropolitan area. For China, the implementation of the sponge city approach is an important and recognised step to make cities fit for the future. Sponge City elements as a combinatorial overall concept help to mitigate urban heat island effects and flash floods, improve groundwater recharge and quality as well as the structural diversity of urban spaces. They basically follow the natural model and impress with their simplicity and efficiency.

Download the brochure ”KEYS–Demonstrations for a smart Sponge City”

The Video of the Stadtwerke Karlsruhe shows the future project of the watersupply treatment plant Mörscher Wald

[Translate to Englisch:] Das Video des Architekten Martin Willms zeigt den Baufortschritt des Wasserwerks

It has been completed: The new construction of the Mörscher Wald waterworks, for which the ground-breaking ceremony took place in November 2018. Commissioning is currently underway and the official inauguration will take place in July 2022. The new waterworks is equipped with state-of-the-art technology and now replaces the 70-year-old plant in the immediate vicinity on a directly adjacent plot of land. After commissioning of the new plant, the existing one will be completely dismantled. For species protection reasons, demolition will not take place until September 2022 and the area will be reforested. In future, the new waterworks will ensure the vital supply of potable water for the city of Karlsruhe and the surrounding communities. Calculations of the potable water demand until 2040 showed that, due to climate change and the predicted population growth, a capacity of 60,000 m³/d or 3,000 m³/h will have to be maintained in the future as the maximum capacity for raw water extraction and treatment. The architectural design of the building provides for a harmonious integration into the greenery. As a partner in a consortium, DAHLEM has been commissioned with the planning of the civil engineering works, the building interiors and the outdoor facilities. A BIM-oriented 3D model was created for the building design.

April 2022

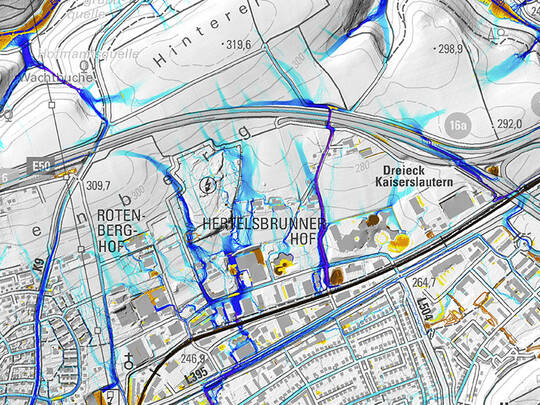

Heavy rainfall events have caused considerable damage throughout Germany in recent years. Municipal decision-makers see themselves more and more obliged to assess the flood risks and derive precautionary concepts in the short term. The flow path analyses used so far for large-scale rough analyses have methodological limitations. Our colleague, Dipl.-Ing. Tim Schneider from Darmstadt, developed on a freelance basis "SplashTool" - software that no longer has many of these limitations. SplashTool was used for the first time for a volume-based flow path analysis and rough analysis over an area of 200 km² for the city of Kaiserslautern and is now used as a tool in numerous projects for heavy rainfall risk management.

Figure l.: Map generated with the help of SplashTool

Further information on SplashTool:

https://www.splashtool.de/

Heavy rainfall hazard maps of the city of Kaiserslautern:

https://ste-kl.de/index.php?id=175

Article in the trade journal wwt Water Management Water Technology dfv.de,

March 2022 issue, p.36 - 39

As part of the Emscher Conversion generation project, the Emschergenossenschaft redesigned also the Katernberger Bach stream, which, for the most of part, has been flowing through the Katernberg district of Essen since the 1960s. Along a stretch of 1,100 metres, the stream was given new space next to the old watercourse route and is now running open along 1.2 kilometres. The opening of the stream and the separation of clean and wastewater as well as the renaturation of obstructed drainage profiles enable an ecological improvement of the watercourse. In addition to the river engineering plans, bed slides, fords and a bridge as well as several culvert structures have been implemented. Accompanying measures along the ecologically revitalized watercourse enhance the green corridor and create a high recreational quality for the Katernberg district. The Emschergenossenschaft commissioned DAHLEM with the project planning, structural design, technical equipment and construction management for the watercourse conversion.

The illustration shows a visualisation of an accompanying measure:

Waterside playground (Hoff Landscape Architects, Essen).

February 2022

The construction work is complete, wastewater is being delivered via the upgraded sewer systems and treatment has begun. A new, central, fully biological wastewater treatment plant now receives and processes the sewage from the western Kosovan city of Peja. The contractual acceptance date was 1st February 2022 and the local water supplier has now taken over responsibility for operation and maintenance. Planning for the new plant with an initial treatment capacity of 81,000 population equivalents began in February 2018 and WWTP Peja is now one of the first of its kind being operated in Kosovo. The new facility will make a huge contribution to improvements in the quality and the sustainability of both precious local water resources and the living conditions of the Project area’s residents, as well as many of those living downstream. In addition to the treatment, an anaerobic-mesophilic digester stabilises the sewage sludge and CHP units (converting the gases produced to heat and electricity) satisfy much of the plant’s power demand. In the urban areas of Kosovo, sewage systems for wastewater collection are very often available but the country lacks municipal and industrial sewage treatment plants. This means the direct discharge of untreated waste to the environment is widespread, a problem now overcome in Peja. The extensive sewage collection and treatment measures implemented as part of this Project were financed by KfW, SECO, local funds from the municipality and the government of the Republic of Kosovo itself. The total costs for the design and construction of around 8 kilometres of new sewage collection and conveyance systems, stormwater overflows and the wastewater treatment plant amounted to around € 23 million. HIDRODINI engaged DAHLEM to provide the planning, tendering and procurement and construction supervision services for both the sewage treatment plant and the additional sewers.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/2/csm_2023_Folder_BIM2WATER_799faf6466.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/c/csm_Newsslider_KA_Peja_Nachtaufnahme_2_bbe2516799.jpg)